Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

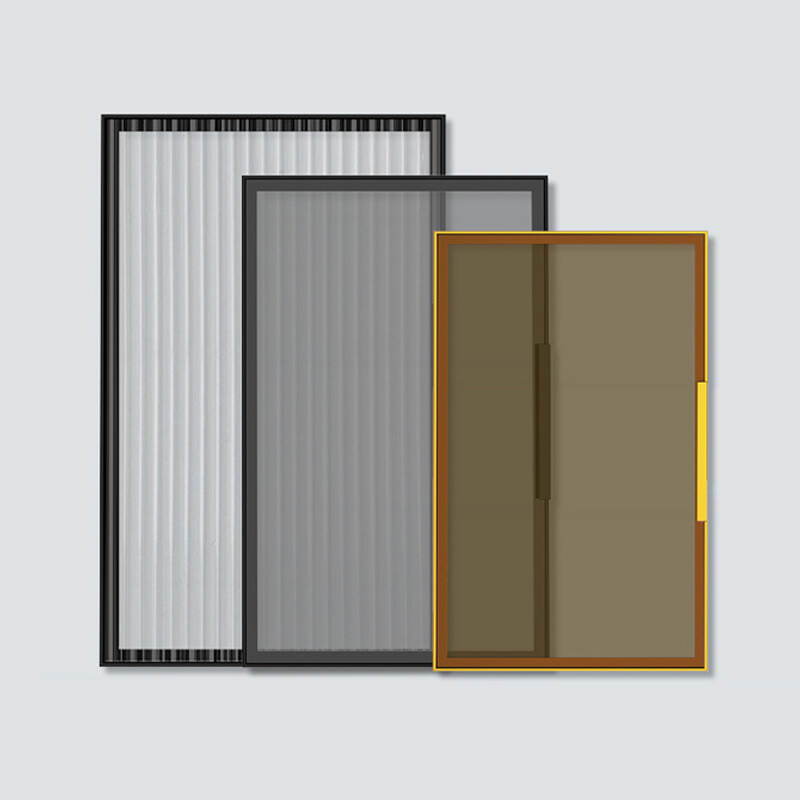

20mm F-shape handle framed cabinet door minimalist glass sliding door aluminum alloy

The aluminum alloy cabinet door profile process includes the main processes of batching, smelting, casting and so on. The ingot with certain chemical composition and external dimensions are formed.

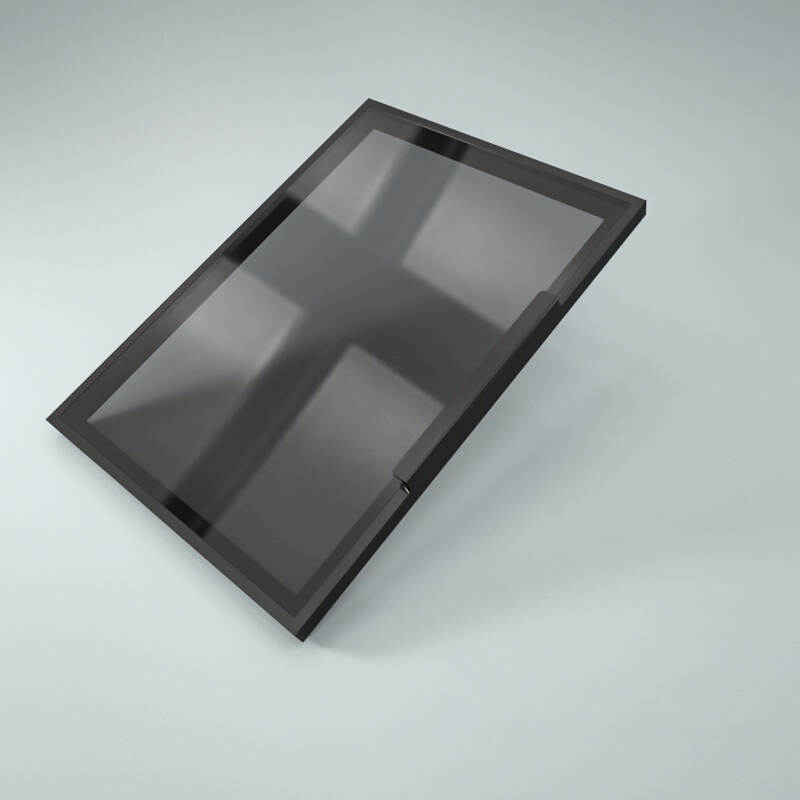

Product Description of Custom-Made-Size Cabinet Doors

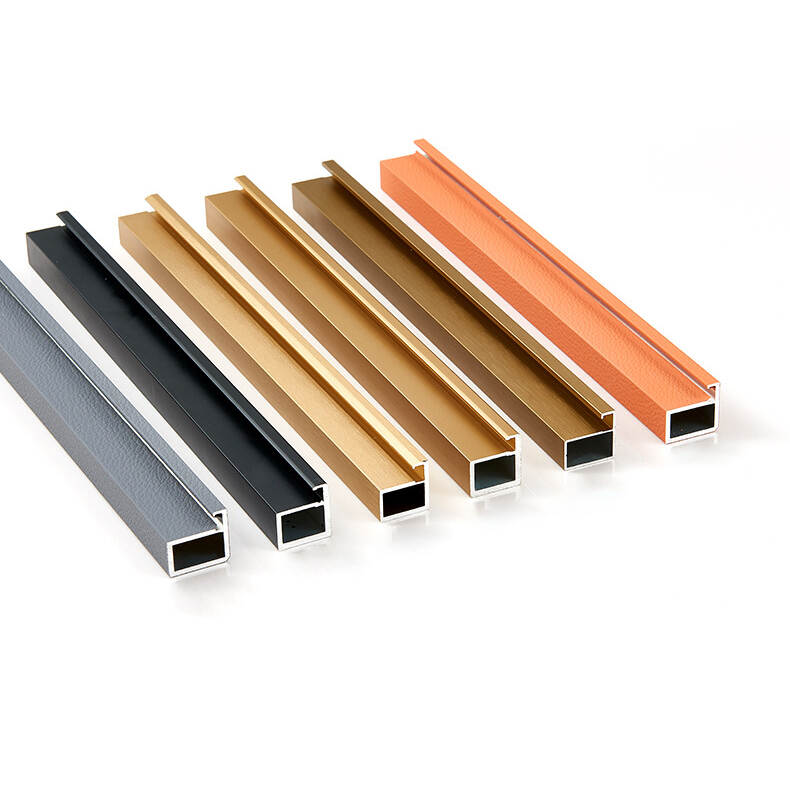

Our custom-made-Size cabinet doors are made with high-quality aluminium extrusion profile 6063, ensuring strength and durability for long-lasting use. We offer a variety of shapes, including hollow and non-hollow profiles, square, rectangle, round, flat, and angle, providing endless possibilities for customization.

Product Services of Custom-Made-Size Cabinet Doors

In addition to the range of shapes available, we also offer a variety of surface treatments to choose from. Our anodized treatment enhances the appearance of the doors and prolongs their service life, while our powder-coated treatment provides a more durable finish. For those looking for a more polished look, we offer a polished surface treatment, and for those desiring a more natural look, we offer a wooden surface treatment.

We also provide customization options, allowing customers to add their brand and logo to the doors. A range of colours is also available, including silver, champagne, bronze, and black, ensuring that customers can find the perfect match for their needs.

Our Aluminium Alloy Cabinet Door Profile Production Process

Our production process includes casting, extrusion, heat treatment, and surface treatment. Each step is carefully monitored to ensure that the final product meets our high standards.

Product Features and Advantages of Custom-Made-Size Cabinet Doors

Our doors are made with a reinforced aluminium-magnesium-silicon-based aluminium alloy, providing proper mechanical properties and ensuring that the doors are strong and durable. Our anodized surface treatment not only enhances the appearance of the doors but also prolongs their service life, making them a great investment for any project.

We also offer a range of accessories for easy installation, making the process stress-free for our customers. Our small-profile insert and cutting processing services are available with a tolerance of 1%, ensuring that customers receive exactly what they need. With a supply capability of 30000 metric tonnes per year and a lead time of 15-20 days, we are committed to providing our customers with high-quality products and timely service.

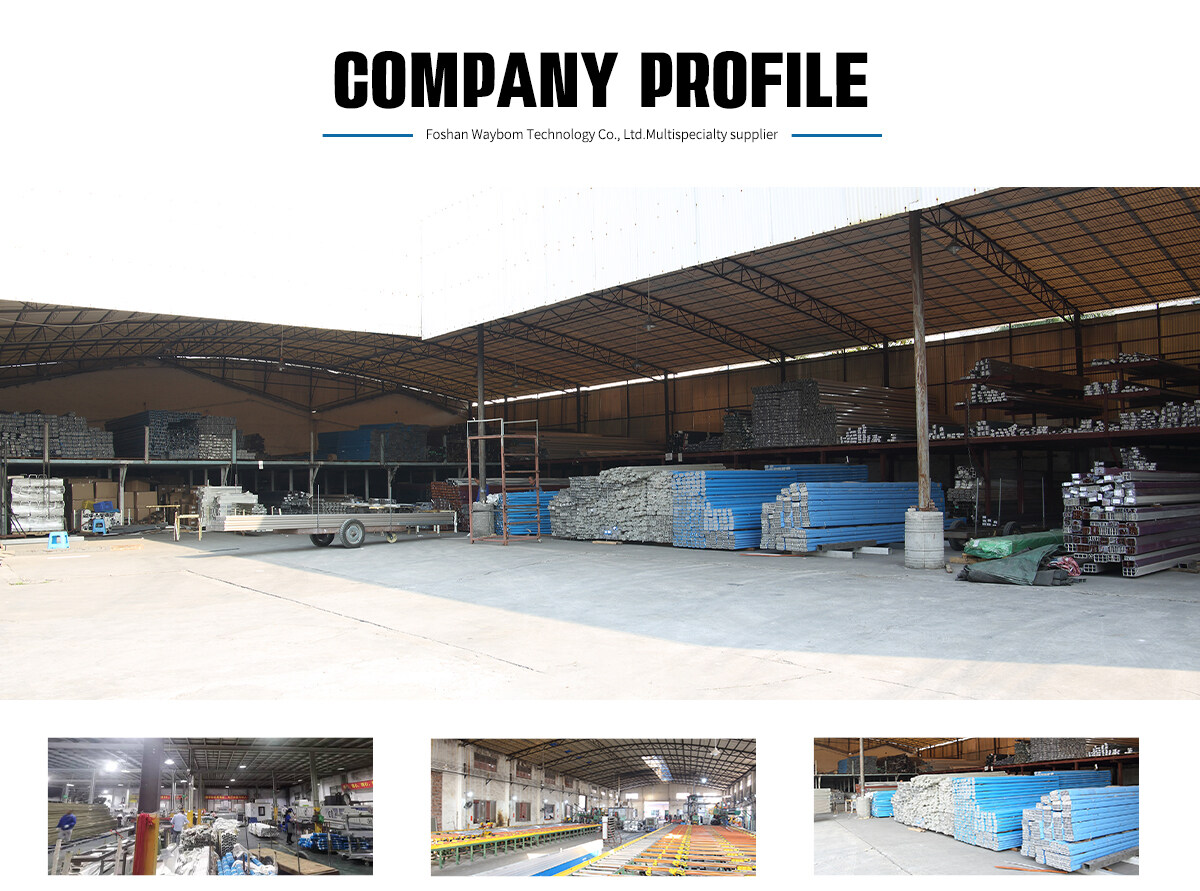

Our factory was established in 2008, covers an area of 56,368 square meters, has 176 employees. With 5 aluminum production lines, 20 CNC machining centers, 2 powder coating lines, several anodizing tanks, Polishing, brushing and sand blasting equipments, Well-established packaging and quality inspection system, our annual output of aluminum is 15000 tons, and more than 20,000 sets of finished products. We can satisfy your demands quickly from our stock or produce your own design. We do ODM and OEM.

We choose A0 degree aluminum ingot as raw material.

The most used 6063-T5 and 6061-T6 aluminum alloy comply with national standards GB/T5237.

We do extruding with designed moulds to get different shape of profiles.

The strength and toughness of the profiles are ensured by aging treatments.

Surface treatment like powder coating, anodizing and electrophosis are required to protect the profile and get good-looking surface.

We do offer machining services like milling, drilling, bending, threading, etc.

All products will be inspected strictly before packing.

After you place your order, we will check again and suggest you the best packaging method based on different shapes of products (including but not limited to kraft paper packaging/bubble wrap/wooden box packaging).

We provide different packages for different products to make sure the goods can stay good during long-time shipping. And we can do customization according to your requirement.

Usually we will use kraft paper, bubble wrap, plastic protective film, cartons, wood crate and pallet, ect.

Usually we need 15-45 days for production, and we would communicate with customers about all details for shipping a week earlier before goods are ready.

Either you have shipping agents or not, we can assist you to ship the goods and provide you documents for custom clearance. And door to door shipping is also available.